Turning up the Heat on Energy Recovery!

Stinebaugh & Company represents Tempeff, with Dual Core™ Technology, offering the highest quality energy recovery equipment with the highest efficiency available.

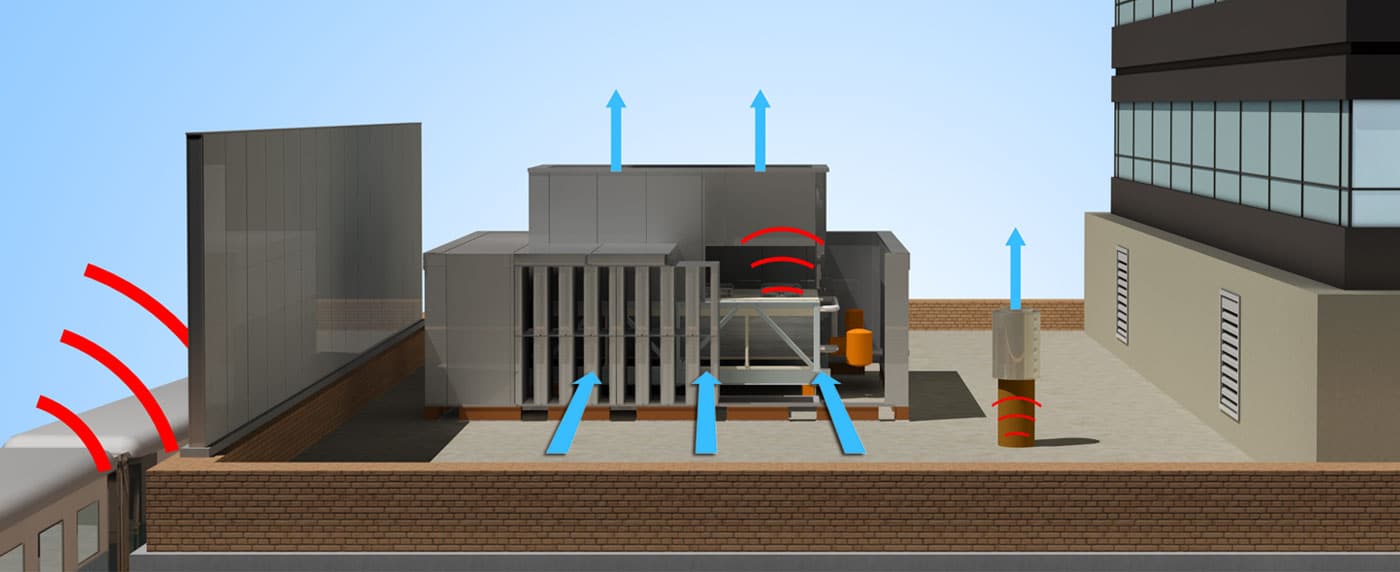

The Dual Core Difference

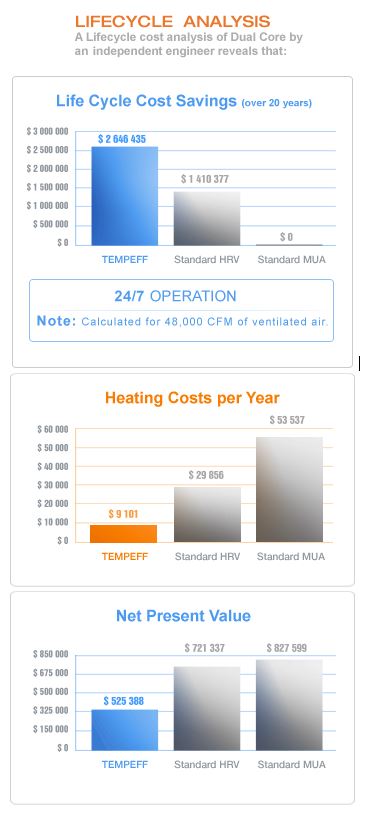

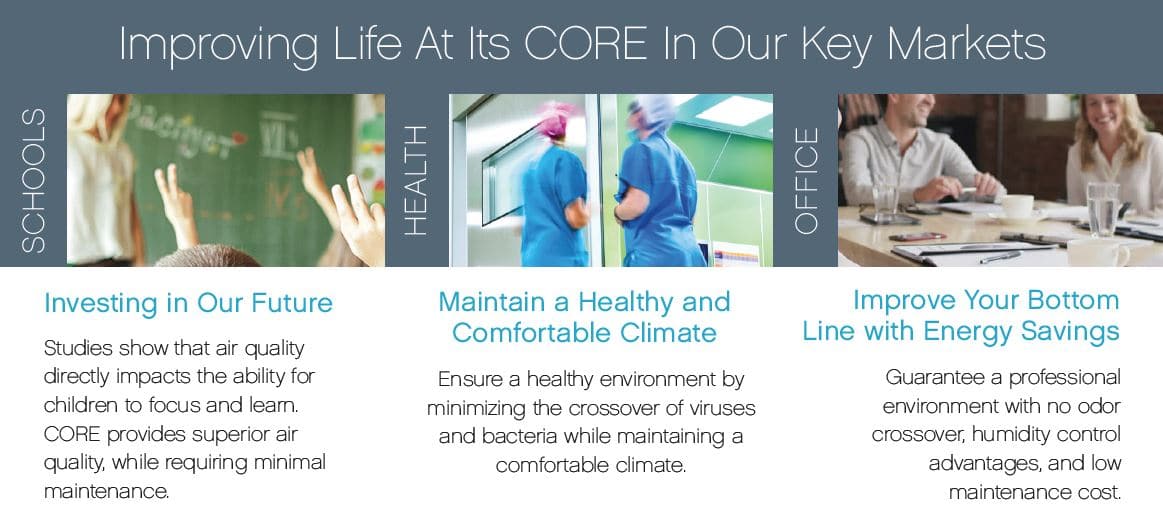

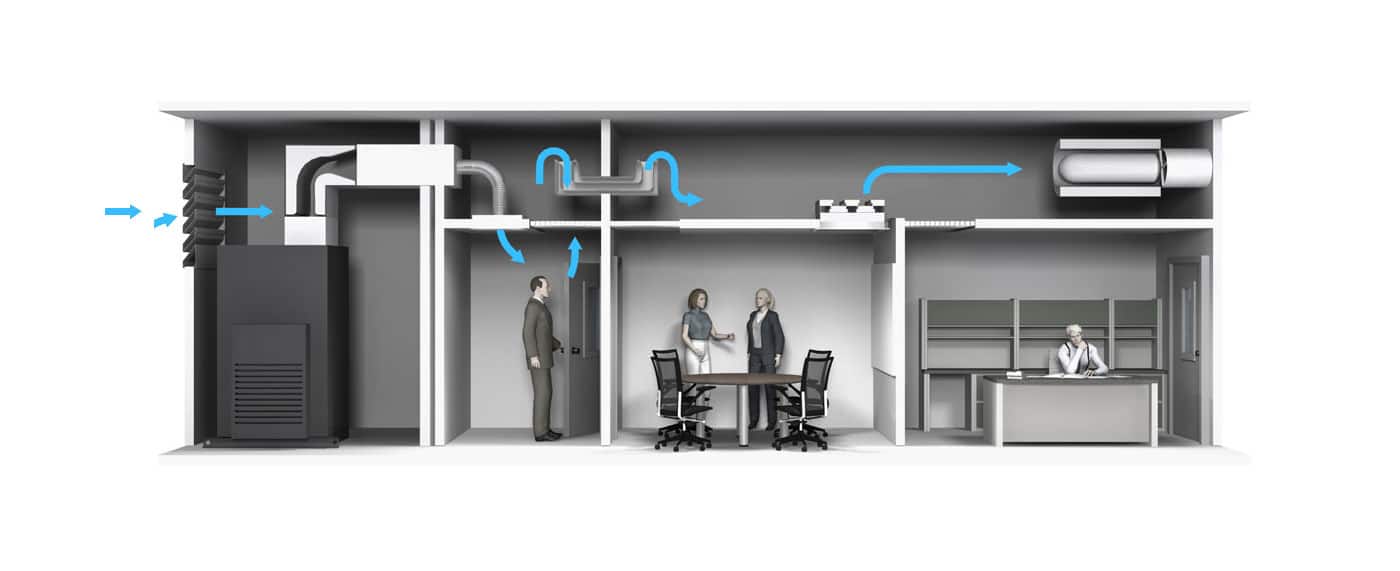

Any building owner or operator knows that due to the extreme North American climate, conditioning ventilation air is very expensive. Ventilation air is extremely important to ensure the building is healthy and in turn the occupants are healthy and productive. Thanks to Tempeff Dual Core’s high efficiencies, owners can meet or exceed minimum legislated ventilation requirements, without the usual high operating costs of traditional ventilation heating and cooling equipment.

Other available technologies offer a maximum of 50-75% efficiency under ideal circumstances, and much lower real effectiveness in colder temperatures due to frost. Our Dual Core™ design is significantly more energy efficient in all conditions, without any requirement for a defrost strategy, thus true operating costs are extremely attractive.

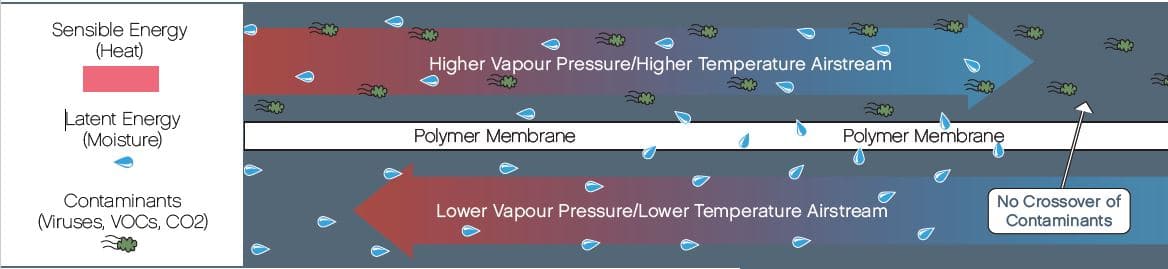

Obtain up to 70% latent recovery

In winter modes condensation will form on the exhausting heat exchanger. When the cycle changes, the outdoor air is passed over the heat exchanger and that moisture is added back to the airstream. This reduces the need for added humidity in the conditioned space.

Resist frost while maintaining effectiveness

Most heat recovery technologies suffer from the same basic drawback. In cold temperatures, frost forms on the exhaust side of the heat exchanger. This dramatically reduces the heat recovery effectiveness and drives up true operating costs. With the Dual Core™ design frost will never build up in a typical application. By employing a cycling heat exchanger, frost doesn’t have a chance to form, and one heat exchanger is always delivering conditioned air to the space.

Lower the maintenance of your system

With few moving parts, maintenance of the system is very low. Due to the cycling nature of the heat exchangers dust rarely builds up on the heat exchangers, eliminating the need for frequent cleaning.

In a third party audit of a 17 year old installation, performed by CIT Energy Management AB, it was found that the efficiency of the equipment was the same as the day it was installed (90% measured temperature efficiency). Owners of Tempeff equipment can rest assured that the high efficiency achieved will not diminish over time.

Please call Maile Guieb, Zach Keller, or Doug Franklin for more information today!