ONICON HVAC Flow and Energy Measurement Solutions

ONICON Incorporated has been delivering market leading flow and energy measurement products since 1987. For over 30 years ONICON has been delivering quality engineered flow and energy measurement instruments for hydronic heating and cooling systems.

ONICON’s broad range of product solutions are wet-calibrated, fully programmed for your application, and ready to use right out of the box. This attention to detail simplifies installation and maximizes performance. ONICON’S flow meter technologies include: electromagnetic, turbine, ultrasonic, thermal, and vortex. ONICON also offers BTU (energy) meters that integrate flow inputs from the technology of your choice.

Do you want more information about ONICON? Please contact Shawn Darmody today!

Specific Systems: Severe Duty and Explosion Proof HVAC

Engineered for performance and durability in the world’s most difficult environments.

Specific Systems® InPac™ Series wall-mounted industrial severe duty and explosion proof HVAC units are engineered and proven to provide safe air conditioning and stand up to the rigors and harsh conditions of corrosive and hazardous environments, including those found in refineries, water/wastewater treatment plants, and on oil drilling rigs and offshore processing plants.

- Available for use in hazardous Class I, Division 1, Groups C, & D locations, as well as Class I, Division 2, Groups B, C, & D

- Standard through the wall air conditioning configuration

- Also configurable in Wall Mount, Pad Mount, Roof Mount, or Split configurations, using the same components for reduced lifetime costs

- Built to demanding industrial specifications

- Innovative two-stage dual refrigeration circuit provides 50% redundancy on units over 3 tons

- Available corrosion resistant coatings and many other options

- CSA certification, UL Listed panels, with ATEX and IECEX certification available.

InPac™ units include as standard what many others consider modifications or special features. Beginning with 16-gauge powder coated galvanized steel cabinets with stainless steel fasteners and drain pans, InPacs are industrial duty by design.

Industrial Cabinet Construction

- 16-gauge or heavier 316L stainless steel is standard

- Optional 304 stainless steel, hot-dipped galvanized steel, or aluminum

- Galvanized steel and aluminum are powdercoated in-house to a thickness of four mils, with several colors available

Redundancy: Built-in

Dual Fans

Providing conditioned air into a space is the main purpose of an ECU, and InPac™ units are built to deliver.

- Units from two tons (24,000 BTUH) to 50 tons (600,000 BTUH) utilize dual spark-proof evaporator blower assemblies

- Two forward-curved blowers run concurrently on a double-shafted industrial grade motor

- Two additional blowers can be optioned to serve as redundant backups

- Main and aux fans are used to purge and pressurize the area in the event of a pressure loss, if required

- Spark-proof axial condenser fans are standard on InPac units

Evaporator and Condenser Coils

- Standard coils are constructed from heavy-weight rifled copper tubes mechanically bonded to aluminum fins

- Standard coils can be coated with our SpecificCoat™ two-stage corrosion resistant coating, designed to give you optimal protection with minimal loss of heat transfer

- All InPac™ evaporator and condenser coils interlace two completely separate refrigeration circuits

- This allows the InPac™ unit footprint to remain as small as possible while still offering the redundancy and efficiency of four separate coils.

- Condenser coils are designed at 8 FPI to reduce clogging in industrial environments

- Evaporator coils are designed at 11-13 FPI for efficiency

- Highly corrosion resistant copper fin/copper tube coils are available as an option

- Several corrosion resistant coatings are also available as options

- Freezestats are also standard on all InPac™ systems

Compressor

- Two hermetically-sealed scroll compressors

- Crankcase heaters are provided as a standard feature to further extend the life of compressors

Control Designed for Ease of Use

Control Systems

- UL 508A Listed and labeled control panels are located in the unit chassis

- Remotely mounted panels are available

- Utilize the most reliable industrial components and modern technology with all wires numbered and labeled for easy recognition during service.

- Basic features of standard InPac™ HVAC control panels include two-stage control on both heating and cooling, automatic switching, and manual override switches for both stages, if desired.

Temperature Control

- Close-tolerance temperature control is provided by a dual-stage digital thermostat

- Remote mounting is available

- Remote temperature and interface control panels capable of controlling multiple individual units from a single location can also be provided

Power Control

Fans, compressors, and other components in standard InPac™ units are automatically shut down by numerous safety devices, depending on any of several overload conditions. Standard fault interrupts on InPac™ units include

- High and low refrigerant pressure on both circuits

- Evaporator coil freeze

- Compressor high current/temp overload

- High temperature in the heating coil

- Fan motor overloads

- Compressor restart delay.

Each of these faults can be wired to trigger a local and remote alarm if desired.

Filtration

- Standard InPac return air filter is a 1″ aluminum frame washable flexible polyurethane foam media (UL Class 2).

- Standard InPac outside air filter is a 2″ Farr 30/30, a MERV-8 pleated panel filter that meets most industrial and commercial filtration requirements.

- Additional chemical filtration and high efficiency filtration, including HEPA, can be provided as shown in the optional equipment list.

Please check with your sales representative for full details on available filtration options.

Alarms

- System failure alarm Form C contacts for each of the two refrigeration circuits are provided on all units.

- Units ordered with the optional NFPA 496 purge & pressurization package also include purge system failure, instantaneous and sustained building pressure loss alarms as standard features.

- All alarms offer one or more Form C dry contacts for interface to remote monitoring systems for notification of an alarm event.

- A multitude of other alarms, as well as unit mounted visual and audible indicators are available as options.

Need more information? Please contact Connor Doyle today!

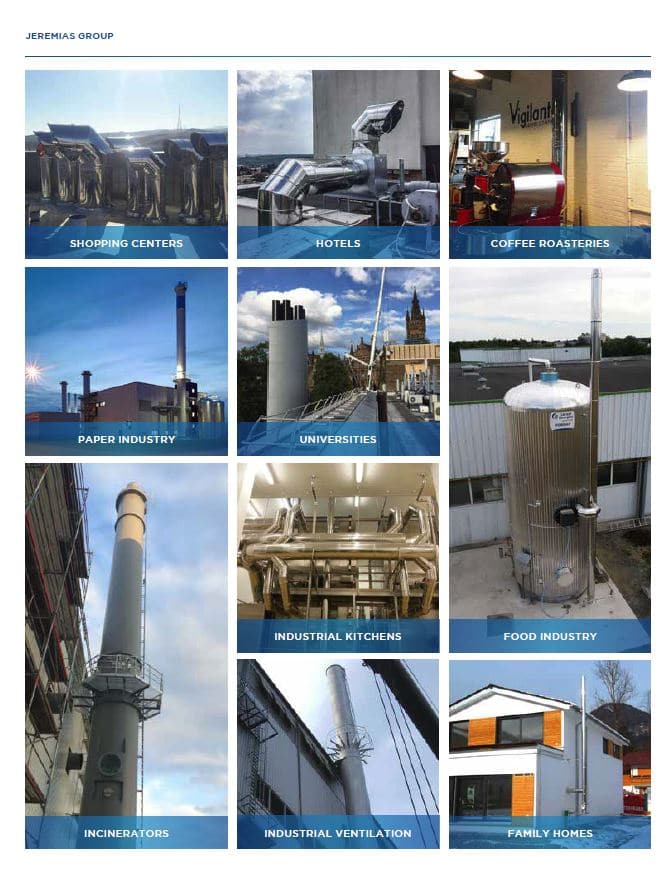

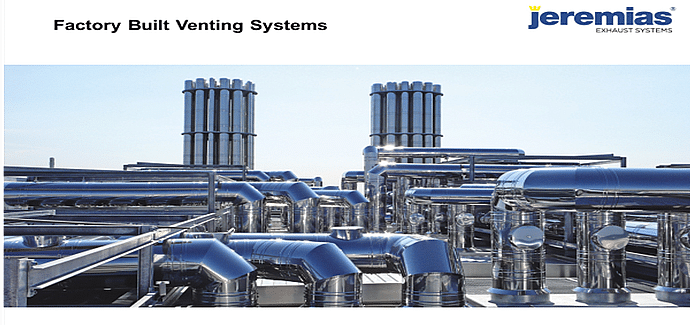

Stinebaugh & Company Now Represents Jeremias Exhaust Systems!

Stinebaugh & Company now represents Jeremias, one of the world`s leading manufacturers of flue and chimney systems for the exhaust of gases and ventilations. Jeremias Group has over 40 years of experience in design, production and development of solutions for exhaust systems.

Want more info? Please contact John Post at Stinebaugh & Company today!

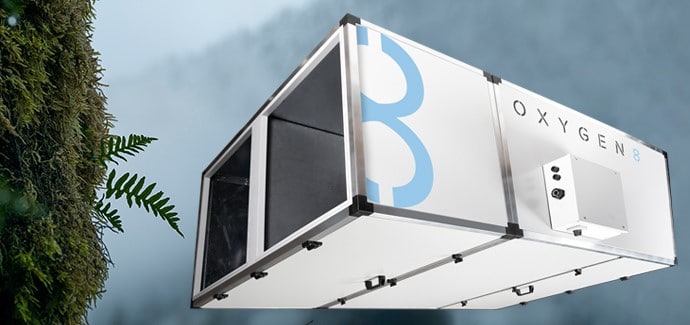

OXYGEN 8: A Breath of Fresh Air for HVAC Design

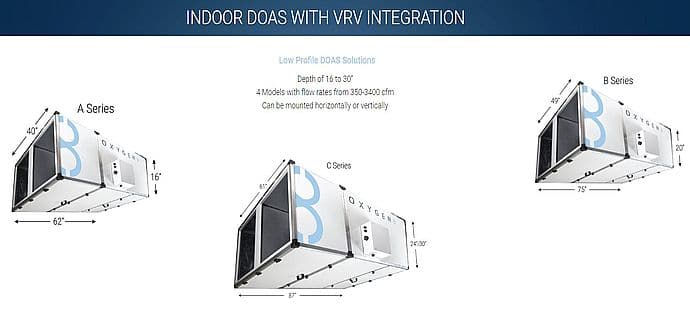

OXYGEN8 : A NEW COMPANY LAUNCHES THEIR LOW PROFILE INDOOR DOAS PRODUCT LINE WITH VRV INTEGRATION

Oxygen8, a new and innovative HVAC equipment design and manufacturing company, launched a line of fully electric Dedicated Outdoor Air Systems (DOAS) to meet the needs of modern building design and to address current human health and climate change challenges.

Oxygen8 systems use membrane based energy recovery technology and integrate Daikin’s VRV heating and cooling systems to provide 100% fresh, filtered air to indoor environments at ideal temperature and humidity levels. The low profile design beautifully integrates into compact spaces and allows for ceiling, wall or floor mounted installation, providing 400-3500cfm of outside air directly indoors, preventing recirculation of air and cross-contamination of airborne viruses and bacteria.

BREATHE HEALTHY WITH HIGH IAQ

Low energy fans, fixed plate enthalpy exchangers and high-MERV filters deliver 100% fresh, outdoor air to designated building zones, eliminating crossover and recirculation of contaminants while keeping relative humidity at healthy levels.

INNOVATIVE DESIGN

Compact (16”, 20”, 24” or 30” deep), decentralized design allows for seamless ceiling or wall installation, ensuring maximum usable floor or roof space, while ECM fans and double wall construction make for a quiet operation.

ENERGY EFFICIENT

100% electric HVAC system with energy recovery makes for a more energy efficient system and small carbon footprint.

SMART SOLUTIONS

Technology connects HVAC systems to smart devices for easy monitoring and maintenance, with real-time filter alerts, demand controlled ventilation, and remote diagnosis.

CLIMATE, CONTROLLED

Connectivity with world leading HVAC equipment from Daikin allows cutting edge, fully integrated ERV and VRV systems that control temperature and humidity levels for unparalleled comfort and health.

EASY INSTALLATION & MAINTENANCE

Pre-installed coils, electronic expansion valves, and controls, plus easy-to-access filters and an ERV core with no moving parts ensures systems are easy to install and maintain.

For more information please contact Doug Franklin today!

ANTEC Controls by Price: Introducing Venturi Valves with Factory Mounted Pace™ Controllers

ANTEC Controls by Price: Introducing Venturi Valves

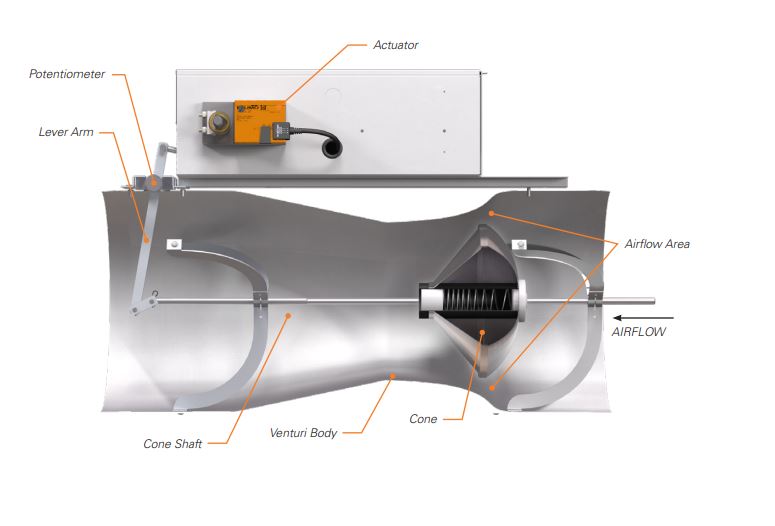

Venturi Valves are mechanically pressure independent airflow control valves designed specifically for room pressure and fume hood control applications.

Available in constant or variable air volume configurations, the Venturi Valve is able to control flow without the need for airflow measuring devices in the airstream. The device eliminates the possibility of lint or other airborne particulates interfering with the control or accuracy of the valve. The valve provides electronic flow feedback using a precision potentiometer to output a signal proportional to airflow.

Each valve is factory characterized on NVLAP accredited airflow calibration stations (NVLAP Lab Code 201067-0 complying with ISO/IEC 17025:2005) using N.I.S.T traceable equipment to ensure dependable and repeatable valve accuracy. Antec Controls Venturi Valves are accurate to ±5% of flow when operated within the designed pressure range. Valve accuracy is unaffected by inlet conditions and does not require any minimum distance of straight duct on the inlet or outlet of the valve.

Mechanical pressure independence is achieved through the highly engineered internal plunger assembly. The plunger assembly ensures the valve responds instantaneously to changes in duct static pressure. Turndown ratios reaching up to 20:1 maximize energy savings when space unoccupied or when at minimum flow set point.

FEATURES

- Electronic airflow feedback prevents dust/ lint contamination from deteriorating airflow reading

- Characterized and calibrated using NVLAP accredited airflow stations

- Medium or low pressure operation

- Operating pressure feedback

Pace™ is a flexible controller for room containment through pressurization. Pace™ delivers seamless environmental monitoring, control and energy savings in critical spaces.

To achieve room pressurization requirements, Pace™ allows for either Volumetric Flow Offset or Pressure Control strategies. Pace™ achieves airflow control utilizing Venturi Valves, Venturi FX valves or Terminal Units.

For more information about ANTEC by Price Venturi Valves with factory mounted Pace™ controllers please contact John Post today!